Precision Die-Cutting & Premium Finishing Services

Precision die-cutting for custom shapes combined with premium finishing options including UV coating, hot foil stamping, embossing, debossing, spot varnish, and lamination. All finishing processes are executed in-house for quality control and faster turnaround.

What Sets Our Die-Cut & Finishing Apart

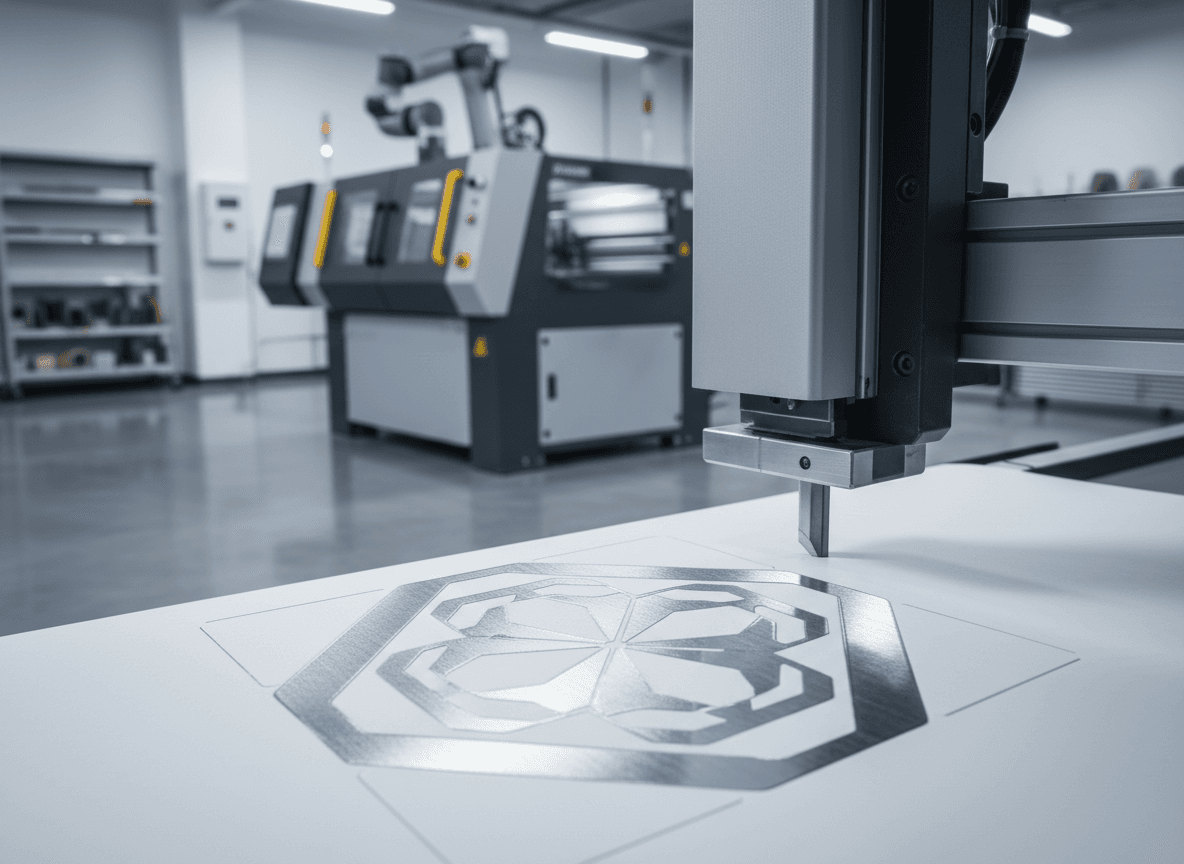

Custom Die Tooling

In-house die design and fabrication for any custom shape. Steel rule dies for standard production and rotary dies for high-volume continuous runs. Die storage program available for repeat orders.

Hot Foil Stamping

Gold, silver, copper, holographic, and custom-color foil stamping for premium brand presentation. Multi-level stamping capability for complex designs with fine detail reproduction.

Embossing & Debossing

Multi-level embossing and debossing with registered placement for tactile brand elements. Combination emboss + foil stamping available for maximum shelf impact.

UV & Spot Varnish

Full flood and spot UV coating for high-gloss accents, soft-touch matte varnish for tactile luxury, and raised UV for dimensional texture effects that demand attention.

Lamination Options

Gloss, matte, soft-touch, and anti-scuff lamination for protection and presentation. Available in standard and biodegradable film options for sustainability-focused programs.

Technical Specifications

Materials We Work With

- Coated & Uncoated Paper Stock

- Card Stock (250–450 gsm)

- Corrugated Board

- Vinyl & Synthetic Films

- Magnetic Sheet

- Clear PET & BOPP Films

Common Use Cases

- ■Custom-shaped labels & stickers

- ■Premium packaging with foil accents

- ■Luxury business cards & stationery

- ■Custom-shape hang tags

- ■Die-cut POS displays

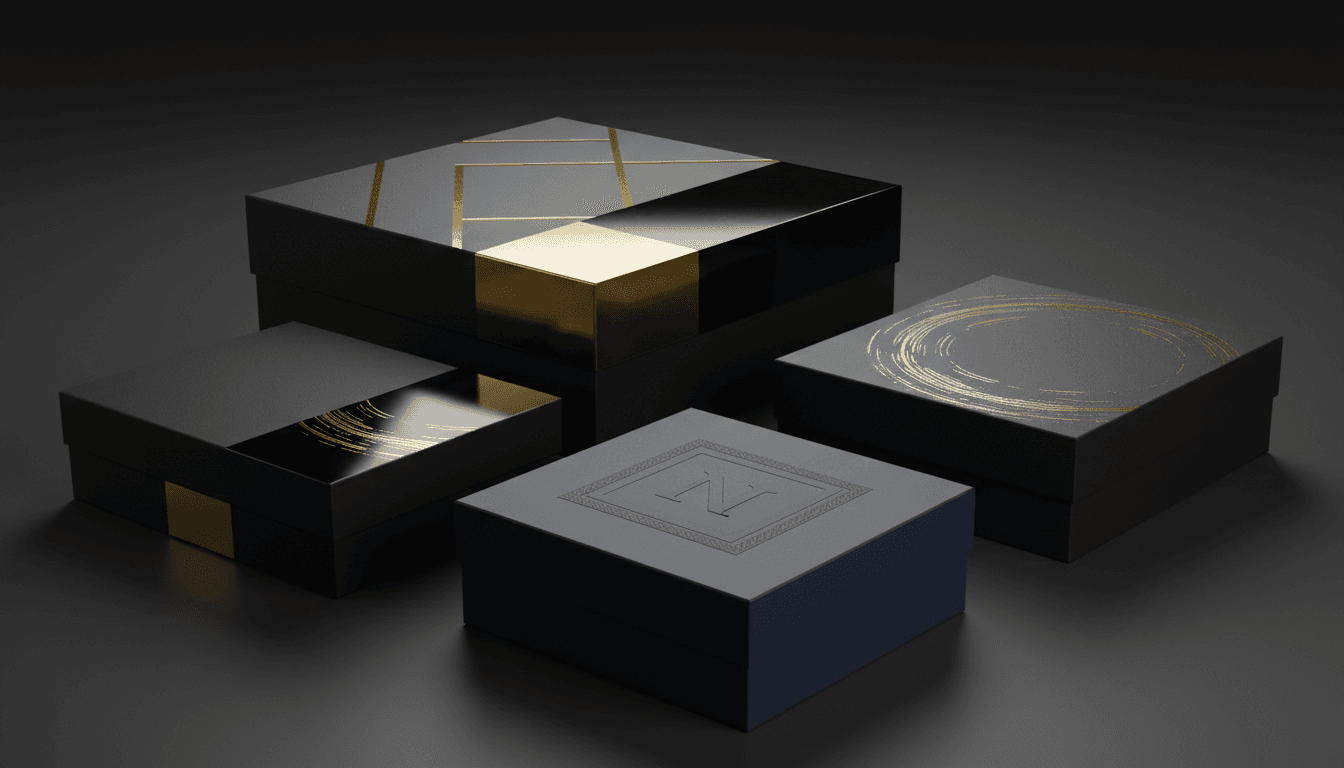

Luxury Cosmetics Brand — Premium Packaging Launch

Challenge

A luxury cosmetics brand required packaging with multi-level embossing, registered hot foil stamping, and soft-touch lamination for a holiday gift set launch — with only a 4-week production window.

Solution

Our in-house tooling team fabricated custom dies and foil plates simultaneously while prepress finalized print files. A 3-pass finishing process (print → laminate → emboss + foil) was executed with registered alignment across all passes.

Result

15,000 premium gift set boxes delivered 3 days ahead of schedule. The client reported a 35% increase in holiday collection sell-through compared to the previous year's standard packaging.

15,000

Units Delivered

3 Days

Delivered Early By

35%

Sell-Through Increase

3 (print + laminate + emboss/foil)

Finishing Passes

Frequently Asked Questions

Do I need to pay for new die tooling on every order?

No. We store your die tooling free of charge for up to 2 years. Repeat orders use the existing die at no additional tooling cost. New die charges only apply to first-time shapes or design revisions that require a new die.

Can you combine multiple finishing techniques on a single product?

Yes. We regularly combine techniques — for example, spot UV with matte lamination, or foil stamping with multi-level embossing. Our in-house production ensures precise registration across all finishing passes.

What is the turnaround time for orders with premium finishing?

Standard orders with finishing typically ship within 10–18 business days. Rush production is available for select finishing combinations with a 5–7 business day option. Contact us for specific timing based on your finishing requirements.

Explore More Capabilities

Custom Print Production

High-volume offset and on-demand digital production for packaging, labels, inserts, and marketing collateral. Our Heidelberg 6-color press technology delivers consistent color accuracy across production runs of any scale — from 500 to 5,000,000 units.

Learn more →Magnetic / Vinyl / Kraft / SyntheticsSpecialty Materials

Production on 40+ substrate options including magnetic sheets, vinyl decals, kraft paper, synthetic waterproof materials, metallic foils, and clear films. Each material is tested and matched to your specific application requirements — from outdoor durability to food-safe contact surfaces.

Learn more →Banners, Signage & DisplaysLarge Format Production

Wide-format digital and screen printing for banners, trade show displays, point-of-sale signage, vehicle wraps, and architectural graphics. Indoor and outdoor rated materials available with output widths up to 5 meters for maximum visual impact.

Learn more →Industries Using Die-Cut & Finishing

You Might Also Be Interested In

Cosmetics & Beauty

Premium packaging and labels with luxury finishing for beauty brands.

Read more →Retail & E-Commerce Solutions

Custom packaging, labels, and POS displays for retail brands.

Read more →5 Ways to Reduce Print Costs

Enterprise procurement strategies for optimizing print spend.

Read more →Custom Print Production

Offset & digital print manufacturing with Heidelberg 6-color press technology.

Read more →Specialty Materials

Print on 40+ substrates: magnetic, vinyl, kraft, synthetics, and more.

Read more →Large Format Production

Wide-format printing up to 5m for banners, signage, and displays.

Read more →Related Resources

Cosmetics & Beauty Packaging

Premium finishing and luxury packaging for beauty and personal care brands.

Learn more →Custom Print Production

Heidelberg 6-color offset and HP Indigo digital for packaging, labels, and collateral.

Learn more →Specialty Materials Printing

40+ substrates including magnetic, vinyl, kraft, and waterproof synthetics.

Learn more →Ready to Get Started with Die-Cut & Finishing?

Tell us about your project requirements and get a custom quote within 24 hours. No minimums on digital production — start with a prototype and scale to millions.